Sclavos SA

SCLAVOS’s History, starts in 1948, when the company was established in Athens Greece by Spyros Sclavos and Evangelos Skepariotis.

The main business of the company, at the start, was parts manufacturing and repair works for textile machinery.

• In the decade of 50ties SCLAVOS started producing the first fabric dyeing winches.

• In the decade of 60ties SCLAVOS specialized in manufacturing stainless steel modern winches mainly for knitted fabrics.

• In the decade of 70ties and 80ties SCLAVOS developed their first low liquor ratio dyeing machines.

• By the mid 80ties SCLAVOS starts its first exports to Europe.

• By the end of 80ties exports are expanding gradually to the Americas and Asia.

• In 1990 SCLAVOS launched a unique dyeing system called “Twin Soft Flow” System with Plaiter and Excess Liquor by Pass, incorporated in Apollon machine.

• In 1995 SCLAVOS developed and launched a revolutionary continuous washing system under the name Aquachron, and which incorporated in the new Venus machine.

• In the decade of 2000 SCLAVOS developed further the above patented systems, which along with further newly developed unique systems were incorporated in a new series of machines by the name Athena series for dyeing of knits and terry towel fabrics. Athena model has had a tremendous success in more than 35 countries worldwide.

• In 2012 SCLAVOS launches the new model Athena3 with unique features, making the machine very versatile for a big variety of fabrics.

• In 2016 the new upgraded model Athena3A is to be offered in the international market after its launching in ITMA in Milan. Athena3A features are reducing further water energy and chemicals consumptions..

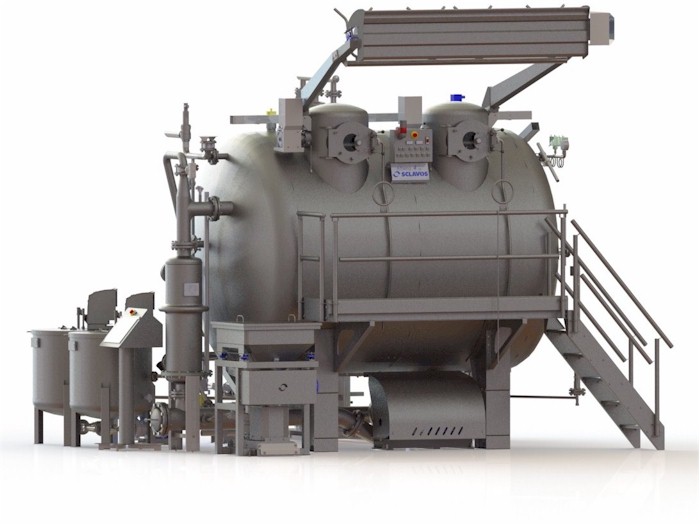

Athena4 incorporates some unique features

- Double Soft Floating dyeing system (DSF)

- Open Plaiter system with Liquor by pass

- Aquachron FLX continuous washing system for nonstop operation

- Flow Balancing Device for assuring smooth machine’s operation independent to utilities network fluctuations

- Safe operation without filter for smooth pump’s running and stable dyeing conditions

- Multi Rope operation system for increased capacity of light weight fabrics

- Automatic Settings Adjustment

- Advanced Automation system for total Interactive control and Industry 4.0 integration

- Full monitoring of utilities consumptions

- Variable Loading System

- Integrated Control of Liquor Ratio

- Low power pump built in house

Benefits that Sclavos can guarantee to users of Athena4

Fabric Quality

- No surface pilling due to mechanical abrasion

- Low tension and shrinkage

- Minimum fiber loss and lint’s creation

- Gentle treatment of delicate fabrics

Performance

- Fast process time

- Low energy consumption

- Minimum water consumption

- Process is not affected at all by utilities network fluctuations or lint accumulation

- Ease of operation

- Batch to batch repeatability

- High capacity for light weight fabrics with no tangles

- “Automatic” washing cycle

- Data for costing calculation

- High reliability due to high end parts use